4 Implementation and Feedback (MONITORING) Optimization

This section addresses site-specific logistical and permitting issues that should be considered before mobilizing to the site as well as during implementation optimization of the remedy to include changes to dose, amendment, and delivery (see Section 1.3). The remedy may be optimized at any stage based on the evaluation of monitoring data.

4.1 Pre-implementation Considerations

Health and safety plans (HASP) and procedures developed during predesign activities should be reviewed and updated prior to field mobilization to protect the health and safety of site workers and the surrounding community. Changes and improvements in safety procedures developed during predesign site characterization, bench testing, and pilot testing should be incorporated before and during optimization of the remedy. In addition to drilling and subsurface utility hazards, in situ remediation also presents some unique health and safety considerations for the injection of reagents and substrates. These include hazards associated with the chemical amendments themselves, application hazards such as increased subsurface pressures or temperatures, reagents surfacing, and post application hazards such as increased byproduct concentrations, metals mobilization, or vapor intrusion (NAVFAC 2013a). Proper engineering controls for these hazards should be identified and included in the HASP (e.g., USEPA Underground Injection Control Regulations)

Pre-implementation considerations also include federal, state, and local regulatory and permitting requirements associated with the implementation and modification of in situ remedies. Inconsistencies between various federal and state programs can present regulatory challenges. As discussed further in Sections 5 and 6, early communication with the relevant regulatory agencies and stakeholders, early start-up on the HASP development, and an understanding of the necessary permitting requirements are critical to facilitate timely regulatory and stakeholder acceptance.

4.2 Adaptive Implementation and Feedback Optimization

Remedy design is an iterative process that unites consideration of site characteristics, amendments, and delivery method. It is important to recognize these truths:

- The data set for a site upon which to develop a CSM and corresponding design will never be perfect or fully complete.

- Factors that influence design cross many orders of magnitude in scale, from the molecular to the site-wide level.

- Site conditions change at time frames that range from minutes to decades.

- Although our models and designs often assume homogeneity, heterogeneity is the rule.

- Amendment transport in the subsurface is (to a first order) dependent upon the site geology, hydrogeology, and delivery method, but nonetheless often seems random and chaotic due to the smaller scale heterogeneities.

It is therefore important to integrate mechanisms for process monitoring, feedback, and flexibility during implementation into the remedial design process.

4.3 Implementation and Optimization Staircase

To conceptualize the iterative process, the design wheel and optimization staircase (see Section 3.1) were developed. Note that in some cases, the results of a bench-scale or pilot test may lead to another bench-scale and/or pilot test before moving into full scale. Optimization is not meant to create an endless cycle of testing and project delays, but to create a remediation strategy that is cost-effective and efficient by targeting the contaminants in the most effective manner. Once the project goes to full scale, this approach is commonly used for subsequent planned injection events, and the monitoring data dictate where and when the next injections will be needed. This approach may not be critical for small, well-understood plumes, but can save millions of dollars and decades of time when the optimization staircase is applied to large, complex plumes (see Section 2.1). At all stages of data collection, consider the cost of collecting analytical data versus the benefit. Also consider the implications of not collecting data, which could result in long-term cost avoidance if properly evaluated.

Within the staircase, there are opportunities to make minimal adjustments to the full-scale remedy. These may be minor adjustments to the remedy that require the practitioner to step back to the pilot study (or bench-scale position if the change is recommended during the pilot study) or make major changes to the remedy that also require return to the bench-scale test. Such decisions are based on a review of the monitoring data and professional judgement. Minimal changes include changes to volume of amendment added, changes in the number of injection points, increasing or decreasing amendment dilution, addition of buffers or bioaugmentation of bioremediation systems, or change in the activator for chemical remedies. Although these changes are considered minimal, some states will require updates to the underground injection control (UIC) permit. Changes that include alterations to the amendment for which stepping back to additional pilot testing is required will likely result in a change to the UIC permit. Major changes, such as moving from bioremediation to chemical oxidation or chemical reduction, may require additional bench-scale testing and may require changes to the decision documents.

4.4 Monitoring

For the purposes of this document, monitoring involves process monitoring and performance monitoring. Multiple lines of evidence are helpful to sufficiently demonstrate that in situ remedies are functioning as designed (Section 4.4.2.3). Therefore, both process and performance monitoring are critical.

- Process monitoring provides an understanding of the operation of the system prior to injection (aboveground), and the postinjection hydraulics, and/or the immediate chemical effect (underground). It also includes the collection and interpretation of monitoring data that provide information on the state of the remedial action during implementation.

- Performance monitoring relates to the collection of monitoring data that provide information on the potential success of the remedial action to achieve remedial goals. It also includes compliance monitoring.

A process and performance monitoring program may involve collection of similar data, and these monitoring plans may be grouped into a single document at some sites; however, the timing of data collection events and the actions taken as a result of the data obtained differ.

4.4.1 Process Monitoring

4.4.1.1 Process Monitoring Design Considerations

4.4.1.2 Process Monitoring Implementation

4.4.1.3 Process Optimization

Process monitoring data should be evaluated in real time, or as close to real time as possible to allow in-field adjustments (optimization) to be made. Because of the real-time aspect of process monitoring, it is essential that experienced field staff be involved in the implementation of the process monitoring plan, and that all staff involved in the remedy implementation are appropriately trained and are aware of the remedy objectives, expected results, and triggers for actions. A comprehensive work plan or field implementation plan should anticipate potential complications in the field and provide a contingency for likely scenarios.

A formal, centralized process should be established to manage and communicate changes made to the original implementation plan as a result of the process monitoring data. Suggestions for this communication pathway are given in (ITRC 2011d). Changes should not be made in isolation, as a change in one area of the implementation methodology may have follow-on effects. The potential impact of that change on future process monitoring data evaluations should be considered and incorporated throughout the optimization process (see Section 4.3).

Table 4-1 provides some examples of observations that may be made during the course of process monitoring, and potential implications. Table 4-1 should not be considered an exhaustive list and there are many site-specific factors that contribute to interpretation of the data. This table represents a few common observations and potential failure mechanisms to be aware of.

Table 4-1 ▼Read more

4.4.2 Performance Monitoring

Performance objectives: ▼Read more

Performance indicators: ▼Read more

Performance metrics: ▼Read more

Performance models: ▼Read more

The performance monitoring strategy should be directly related to the following factors.

- Site and TTZ characteristics, remedial design characterization, and associated CSM, at a resolution and scale(s) applicable to the treatment technology.

- expected behavior of the treatment system under optimal conditions

- common or reasonably anticipated shortcomings in treatment system operation

- common or reasonably anticipated shortcomings in treatment effectiveness

- expected time frame for attaining performance objectives

- compliance objectives

Often, it is useful to implement a data quality objectives (DQO) process to develop and document the technical rationale for a performance monitoring strategy (USEPA 2006a).

Because remedies at many groundwater contamination sites require a long time to achieve completion, performance indicators and metrics specific to interim remedies and goals can be helpful in evaluating progress toward ultimate site closure. Performance indicators and metrics should address:

- remedy operation (e.g. injection rate, ROI, beginning COC concentrations, concentration trends, amendment application rate) (see Section 4.4.1)

- remedy progress (e.g. rates of reduction of contaminant volume and/or mass, COC trends, microbial populations)

- remedial goal attainment (e.g. individual well COC concentration mean and confidence levels, individual well COC trends, overall COC trends, or alternatively, remediation goals based on contaminant flux and/or mass reduction rather than concentration-based goals)

- compliance with specified regulatory metrics

Identification of multiple performance indicators and metrics, consistent with technical approaches based on multiple lines of evidence, typically strengthens the data and information used to support decision-making throughout the remedy implementation process.

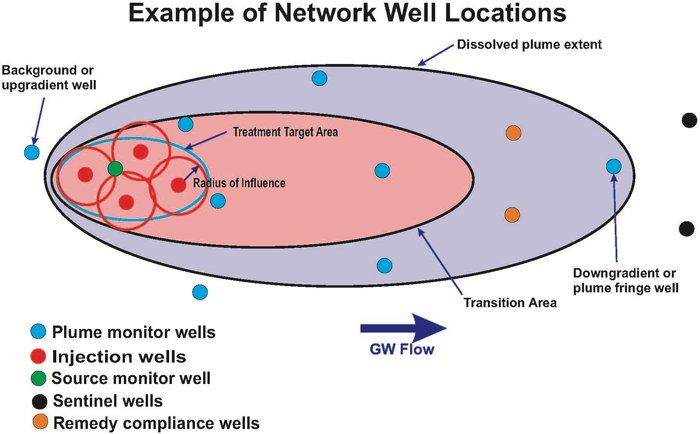

4.4.2.1 Monitoring Well Network

4.4.2.2 Monitoring Schedule

4.4.2.3 Baseline Monitoring

4.4.2.4 Compliance Monitoring

4.4.3 General Parameters

Parameter selection depends on the type of in situ technologies applied. Some general baseline parameters common to various in situ methods are evaluated to measure the effect of in situ remediation relative to remedial objectives, compliance criteria, or operational end points. These parameters may be collected in any and/or all media:

Sampling parameters, timing, and frequency should be selected based on how long the injected amendments are expected to be active and effective. Due to the relatively lower cost and ease of collecting groundwater samples, it is common to collect groundwater samples more frequently during a remedial program. Therefore, most of the discussion in this section focuses on groundwater monitoring. However, professional judgement should be used to determine when, where, and how frequently other media should be sampled and how to evaluate that data.

The geochemical, hydrogeologic, and microbial data should be used to characterize both pre-implementation chemical conditions and hydrogeologic conditions (see Section 2.2). Evaluation of chemical, physical, or biological processes in the subsurface that affect remedy performance and the distribution of COCs depends on the media monitored and potential exposure pathways. Subsurface media may include NAPL, aquifer matrix materials, soil gas, groundwater, seeps, and surface water. If feasible, the preinjection degradation rates should be compared to postinjection rates to measure the effectiveness of in situ technology relative to natural attenuation. Some suggested baseline monitoring parameters that may be applicable are listed below and should serve as a starting point for a site-specific parameter list. Based on site-specific conditions and remedial objectives, additional parameters may be warranted as discussed in Section 2.3 and Section 4.4.4. Further information may also be found in the Appendix A fact sheets for various amendments.

Groundwater Elevations: ▼Read more

Tracers: ▼Read more

Field and Water Quality Parameter Measurement: ▼Read more

General Geochemistry: ▼Read more

Metals Concentrations: ▼Read more

Specific Amendments and Parameters: ▼Read more

Contaminants of Concern Analysis: ▼Read more

Contaminant Breakdown and End Products: ▼Read more

Compound-Specific Isotopic Analysis (CSIA): ▼Read more

Microbial Analysis: ▼Read more

4.4.4 Technology-Specific Parameters

The following tables describe some of the analytical parameters that may be used to monitor the performance of various remedies. Although not meant to be prescriptive or exhaustive, the information in the tables can be used to develop a site-specific monitoring plan. For certain amendments, such as activated carbon-based injectates, the general parameters described in Section 4.4.3 are sufficient. Additional information is available in the amendment-specific fact sheets in Appendix A. The general categories include:

- anaerobic biostimulation (Table 4-2 and A1.2, A1.3, A1.4, A3.1, A3.2, A3.3)

- aerobic biostimulation (Table 4-3 and A1.1, A1.2, A1.4, A3.1, A3.2, A3.3)

- chemical oxidation (Table 4-4 and A2.1, A3.2)

- chemical reduction (Table 4-5, A2.2, A2.3, A3.2)

- surfactant and co-solvent flushing (Table 4-6, A2.5)

Table 4-2. Analytical parameters for anaerobic biostimulation (with or without bioaugmentation).

| Parameter | Interpretation Guidelines | Recommendations |

|---|---|---|

| Contaminant concentrations | Progress is denoted by a reduction of parent COC concentrations and an increase in degradation products; build-up of degradation products could signal stalling. | If parent concentrations are declining but degradation products are not produced, there may be an alternate pathway (e.g., abiotic instead of reductive dechlorination). |

| Contaminant breakdown products | Breakdown products should be short-lived and reduce with time if the degradation is continuing to the desired end products. Changes in total molar concentrations of the parent and breakdown products should be assessed to verify full degradation. | If undesirable breakdown products continue to increase, then adjustments may be needed to stimulate greater transformation toward the desired end products. |

| Ultimate end products (e.g., methane, ethene, ethane, chloride, propene) | Presence confirms degradation of chlorinated solvents or conditions suitable for sulfate reduction and methanogenesis. | If sulfate reduction and methane are not observed and ORP is greater than approximately –120 mV, conditions do not exist for sulfate reduction and methanogenesis that support dechlorination. |

| Field parameters—pH | Microbes typically require neutral pH (optimal range is 6.8–7.5; generally required range is 6.0–8.5). | Select microbial consortia that are suited for low pH environments. Amend with sodium bicarbonate, sodium carbonate, or other additives to adjust pH; verify distribution if amendment is unsuccessful. |

| Field parameters—DO and ORP | DO should be <0.5 mg/l and ORP should be negative; if DO and ORP values are conflicting, the treatment zone may not be properly buffered or gases formed by injected materials may be causing instruments to read incorrectly. | If high DO or high ORP is observed in pockets, anisotropy may be hindering distribution by lowering the ROI in certain areas. Evaluate injection spacing in these areas to improve coverage. Under neutral pH, denitrification occurs when ORP values are between +50 and –50 mV; sulfate-reducing between –50 and –250 mV, and methanogenesis occurs at –200 to –400 mV. |

| Field parameters (e.g., temperature, specific conductance) | An increase in temperature or specific conductance may indicate injection reagents transport and could be used to evaluate ROI. | Each species of bacteria has an optimal range of temperature for growth. Verify that selected consortia meet site characteristics during the selection process because aquifer temperature cannot be changed. |

| Water level and NAPL thickness | Mounding or increased hydraulic gradients can be induced during injection events. NAPL can also be mobilized. | Determine groundwater flow direction and the hydraulic connection between injection wells and monitoring wells. |

| TOC | TOC includes both naturally occurring organic carbon (such as humus) and organic carbon contamination, e.g., benzene. TOC values above approximately 50 mg/L indicate carbon levels that, if biologically available, could foster cometabolism. | Over time TOC will decline again to pre-remediation levels. This, combined with aquifer flow and transport information, can indicate when the substrate is depleted. |

| Tracers (e.g., bromide, potassium, TOC) | If carbon or nutrients are injected, they can be used as a tracer to evaluate ROI and calculate travel times. TOC is an indicator of donor longevity, and trend analysis should predict when secondary injection is necessary. | If tracers are not observed where anticipated, review best practices for emplacement techniques. The sorption of carbon amendments to aquifer material complicates delivery. |

| Ferrous (Fe+2) and ferric (Fe+3) iron and other site-specific metals | The ratio of ferrous (Fe+2) to ferric (Fe+3) provides information on how reducing the groundwater is, the potential for abiotic reductive dechlorination via ferrous iron, and the presence of iron as electron acceptors for biological activity. | Under reducing conditions, ferric iron will pick up an electron to become ferrous iron. If the observed ratio is not as expected, this is an indication that ideal conditions have not been established. Ferrous iron values >1 mg/L are indicative of iron reduction in the absence of nitrate. |

| Reduced or mobilized metals (Mn-2, Cr+6, As+3) | Various metals may be naturally present in groundwater based on provenance and mineralogy. | These should be assessed on a site-specific basis as part of in situ remediation planning. |

| Alkalinity | Alkalinity should be >20 mg/L or fermentation may cause further decline in pH. | Select a buffering agent such as calcium carbonate that improves the alkalinity. Alkalinity needs to be sufficient to allow proper buffering so pH does not drop as a result of acids generated during the fermentation process. |

| Sulfate/sulfite/sulfide | Sulfate concentration <20 mg/l is indicative of sulfate-reducing conditions. | Amendment dosing should be designed to reduce high sulfate when present. If hydrogen sulfide is formed, this can be toxic to microbes. |

| Nitrate/nitrite | Nitrate is the first choice for electron acceptor after oxygen is depleted and generates a sequence of byproducts consisting of nitrite ions and gases (nitric oxide, nitrous oxide, and nitrogen). | Amendment dosing should be designed to reduce high nitrate when present; nitrite may be observed when nitrate is reduced. Nitrate concentrations <1 mg/L are indicative of denitrification. |

| Volatile fatty acids (VFAs) (e.g., lactic acid, acetic acid, pyruvic acid, propionic acid, butyric acid) | Presence confirms the fermentation of carbon substrates such as EVO and lecithin. | If VFAs are not present in an area with high TOC, then fermentation is not occurring. Determine if pH, DO, and ORP need to be adjusted to promote biological activity. If VFAs are present, assess whether the proper microbial consortia are present. Amend if necessary. |

| Vapor measurements (e.g., PID, USEPA Method TO-15, LEL) | High levels of gases are an indicator of both successful bioremediation and potential health and safety or vapor intrusion concerns. | Evaluate risk of vapor intrusion and/or dangerous gas levels. Mitigate if necessary. Reduce frequency of injections to control methane. Verify pH has not dropped. |

| Microbial analysis—gene-specific Section 4.4.3 and 4.4.4.1) | Microbial analysis evaluates a wide range of anaerobic and aerobic degraders. Dehalococcoides mccartyi (DHC) and DHC-related strains are known to degrade chlorinated ethenes; DHB (Dehalobacter) strains are known to degrade chlorinated ethanes and methanes; DHG (Dehalogenimonas) strains are known to degrade chlorinated propanes and chlorinated ethenes; vinyl chloride reductase gene is known to convert VC to ethene (commonly referred to as vinyl chloride reductase (VCR) and BAV genes). | Evaluate if useful microbes are present or if competing microbes are hindering remediation. Microbial analysis provides quantification of important organisms and functional genes responsible for biodegradation of a group of contaminants and therefore more comprehensive site assessment (ITRC 2011b, c). |

| Use when degradation of parent COCs and/or daughter products is not discernable and is required. | Verify anaerobic microbial populations are present; if not, consider amending. |

Table 4-3. Analytical parameters for aerobic biostimulation (with or without bioaugmentation)

| Parameter | Interpretation Guidelines | Recommendations |

|---|---|---|

| Contaminant concentrations | Progress is denoted by a reduction of parent COC concentrations; byproducts detection may be difficult. Seasonal or water table fluctuations should be taken into consideration. | If parent concentrations are declining but degradation products are not produced, may be an alternate pathway. Look for ultimate end products or CSIA data to prove degradation. |

| Contaminant breakdown products | Breakdown products should be short-lived and reduce with time if the degradation is continuing to the desired end products. | If undesirable breakdown products continue to increase, then adjustments may be needed to stimulate greater transformation toward the desired end products. |

| Ultimate end products (e.g., oxygen and CO2 gases, dissolved CO2) | Presence confirms aerobic degradation to end products. | These end products may quickly dissipate in the vadose zone. |

| Field parameters (e.g., pH, temperature, specific conductance, DO, ORP) | Microbes typically require neutral pH (ideal range is 6.0–8). | Adjust pH if necessary. |

| Field parameters—DO and ORP | DO should be >2 mg/l and ORP should be positive. | If DO or ORP is outside the recommendation, improve oxygen distribution. |

| Water level and NAPL thickness | Mounding or increased hydraulic gradients can be induced during injection events. NAPL can also be mobilized. | Determine groundwater flow direction and the hydraulic connection between injection wells and monitoring wells. |

| Tracers (e.g., bromide, potassium, TOC) | If gas carbon or nutrients are injected, they can be used as a tracer to evaluate ROI and calculate travel times. Elevated nutrients can be an indicator of donor longevity and trend analysis should predict when additional injection is necessary. | Observe ROI and travel times. |

| Water quality parameters (e.g., sulfate/sulfite, nitrate/nitrite, alkalinity, propane, TDS) | High TDS can be inhibitory to microbial activity. | For aerobic cometabolic bioremediation of CVOCs and 1,4-dioxane, propane may be necessary. |

| Microbial analysis—gene-specific or QuantArray (Section 4.4.3 and 4.4.4.1) | QuantArray evaluates a wide range of aerobic and anaerobic degraders. | Evaluate if useful microbes are present or if competing microbes are hindering remediation. |

| CSIA (Section 4.3 and Section 4.4.4.2) | Use when degradation of parent COCs is not discernable and is required. | Verify aerobic microbial populations are present; if not, consider amending. |

Table 4-4. Analytical parameters for chemical oxidation

| Parameter | Interpretation guidelines | Recommendations |

|---|---|---|

| Contaminant concentrations | Progress is denoted by a reduction of parent COC concentrations. | If COC concentrations are unchanged, evaluate distribution and effectiveness of selected oxidant (e.g., permanganate will not oxidize ethanes). |

| Contaminant breakdown products | Breakdown products should be short-lived and reduce with time if the degradation is continuing to the desired end products. | If undesirable breakdown products continue to increase, then adjustments may be needed to stimulate greater transformation toward the desired end products. |

| Ultimate end products (e.g., acetone, carbon disulfide, carbon dioxide, chloride) | Presence confirms degradation. | These end products may quickly dissipate in the vadose zone. |

| Field parameters (e.g., pH, temperature, specific conductance, DO, ORP, pressure, ferrous iron, hydrocarbon gases, LEL, CO2) | Certain reactions require low pH (ideal range is 4–6); amend if necessary. In the case of alkaline activation of some oxidants, pH should be confirmed to be above targets, typically in the range of greater than 10.5 and < 12. | Adjust pH as necessary. Temperature and conductivity are often elevated during ISCO application and can be used to evaluate ROI during process monitoring. |

| Water level and NAPL thickness | Mounding or increased hydraulic gradients can be induced during injection events. NAPL can also be mobilized. | Determine groundwater flow direction and the hydraulic connection between injection well locations and monitoring wells. |

| Metals (e.g., arsenic, chromium, lead, zinc, and other site-specific or amendment-specific metals) | Metals can leach from the geology/soil at concentrations that exceed regulatory standards. | Monitor secondary effects of ISCO application. |

| Natural oxidant demand (NOD) | Determine the oxidant demand of the existing biogeochemistry and account for it when calculating the amount of amendment needed. A high NOD may preclude the selection of ISCO as cost-effective. COD, soil oxidant demand (SOD), and total oxidant demand (TOD) are related terms. | Evaluate oxidant demand required to overcome properties of the aquifer. This is typically a design parameter not used during performance monitoring. Multiple applications of a chemical oxidant may be required to overcome NOD such that COD can be adequately addressed. |

| TOC | TOC provides a general indication of the amount of oxidant that will be needed, if a soil sample cannot be collected for testing. | It is best to rely on NOD, COD, or TOD when using chemical oxidation amendments. |

| Amendment-specific parameters (e.g., manganese, sulfate, sodium, potassium, ozone), amendment components (H2O2, persulfate, permanganate, ozone) | Amendments can be used as a tracer to evaluate ROI and calculate travel times if the reaction with contaminants and soil minerals or organics is accounted for. May need to monitor for components of amendments if there are components that present a water quality concern. | Evaluate ROI and travel times. |

| Water quality parameters—TDS | TDS is a measure of the combined organic and inorganic substances in water, primarily minerals and salts. | Some states have compliance values for TDS and/or individual salts or minerals. |

| Sample representativeness | Oxidants such as permanganate and persulfate if present in the groundwater samples after collecting for analysis may continue to oxidize the contaminants slowly until analysis. | Although storing the sample at 4°C may inhibit the oxidation of contaminants, ascorbic acid or sodium ascorbate, as a preservative, is suggested to neutralize the residual oxidant (USEPA 2012b). |

Table 4-5. Analytical parameters for chemical reduction

| Parameter | Interpretation guidelines | Recommendations |

|---|---|---|

| Contaminant concentrations | Monitor change relative to baseline. | If COC concentrations have not been reduced, verify distribution of amendments. |

| Contaminant breakdown products | Breakdown products should be short-lived and reduce with time if the degradation is continuing to the desired end products. | If undesirable breakdown products continue to increase, then adjustments may be needed to stimulate greater transformation toward the desired end products. |

| Secondary water quality impacts (e.g., methyl ethyl ketone and acetone) | Concentrations typically attenuate rapidly to background concentrations (Fowler 2011). | Baseline concentrations of these contaminants should be established and included in performance monitoring to confirm this expected result. |

| Field parameters (e.g., pH, temperature, specific conductance, DO, ORP) | DO should be <1 mg/l and ORP should be negative; specific conductance should be not be affected by ISCR reagents until the iron is converted to ferric or ferrous forms. High specific conductance may suggest fouling. | Evaluate amendment distribution if DO and ORP are not reduced. Under neutral pH, denitrification occurs when ORP values are between +50 and –50 mV; sulfate-reducing between –50 and –250 mV, and methanogenesis occurs at –200 to –400 mV. |

| Water level and NAPL thickness | Mounding or increased hydraulic gradients can be induced during injection events. NAPL can also be mobilized. | Determine groundwater flow direction and the hydraulic connection between injection wells and monitoring wells. Extreme mounding/injection pressures in injection wells may indicate scaling, fouling, or improper construction/development. |

| Water quality parameters—TDS | TDS is a measure of the combined organic and inorganic substances in water, primarily minerals and salts. | Some states have compliance values for TDS and/or individual salts or minerals. |

| Metals (e.g., iron, manganese, arsenic, and other site-specific or amendment-specific metals) | Reduction process can release dissolved concentrations of iron, manganese, and arsenic into the aquifer above water quality standards. | Minimize reduction conditions to the extent practicable while still allowing for desired processes for contaminant reduction. |

| CSIA (Section 4.3 and Section 4.4.4.2) | Degradation of COCs is not discernable and is required (e.g., areas with high concentrations near NAPL). | Use CSIA to discern low levels of degradation |

Table 4-6. Analytical parameters for surfactant and co-solvent flushing

| Parameter | Interpretation guidelines | Recommendations |

|---|---|---|

| Contaminant concentrations | Monitor change relative to baseline. Expect contaminant concentrations to rise at least an order of magnitude, if not more, during the flushing operation and within the flushing zone. If this does not happen then there is likely a problem with the flushing action. | If COC concentrations have not been reduced following the flushing action, verify distribution of amendments. If dissolved COC concentrations have increased in unexpected areas due to surfactant/co-solvent addition, assess need and options for containment/control or removal. |

| Amendment breakdown products | Some co-solvents and surfactants can transform or be biodegraded to other compounds (e.g., certain alcohols to acetone). Breakdown products should be short-lived and reduce with time, but in some cases may pose an exposure risk or treatment challenge. Appropriately specified shear-thinning fluids will rapidly biodegrade, often to low molecular weight organics and carbon dioxide. Limited dihydrogen and methane production is possible. | If undesirable breakdown products continue to increase, then adjustments may be needed to stimulate greater transformation toward the desired end products. |

| NAPL thickness/distribution | The mobilization of NAPL by the amendments would be expected to reduce apparent product thickness in target areas. With effective design and implementation greater than 90–95% NAPL saturation reduction can be expected. If decreases are not observed, adjustments are necessary. Injection may displace NAPL to adjoining areas (laterally or vertically) and lead to increases in NAPL footprint or thickness. NAPL transmissivity can also be estimated, but the change in surface tension of the NAPL due to the amendments may change NAPL transmissivity substantially. | If expected reductions in NAPL thickness and distribution are not observed, reassess injection and recovery spacing, delivery method, or amendment dosage. If NAPL appears to be displaced, assess injection locations (e.g., work from outside inward), pressures, and volumes and consider steps to control or remove displaced NAPL. |

| Water levels | Monitor piezometric response to injection as a line of evidence for amendment delivery flow paths, and possible displacement of NAPL. | If piezometric responses are not observed as expected, evaluate hydrogeology and revise conceptual model; adjust injection and recovery locations, depths, and pressures. 0 |

| NAPL mass/volume recovery | The amount of NAPL recovered indicates fundamental performance of surfactant or co-solvent flushing. NAPL recovery is difficult to accurately quantify due to the amendment/NAPL/water interaction and the likelihood of emulsions. Separation processes can allow better quantification. | The amount of product recovered (relative to baseline, if a recovery system was initially in place before the flushing) is assessed to determine if amendments are contacting the NAPL. Depth and location of injection and recovery are adjusted if recovery changes miss expected levels. |

| Concentration of amendments | Anionic and nonionic surfactant and co-solvent concentrations are monitored to assess the flow paths and adequacy of concentrations for optimally mobilizing NAPL through micelle formation. | Reassess location, depth, volume, and delivery pressure of amendment injections to establish adequate concentrations of surfactants and other components such as shear-thinning fluid polymer to mobilize NAPL. |

| Tracers (e.g., methylene blue active substances (MBAS), cobalt thiocyanate active substances (CTAS)) | Because other subsurface constituents may react with the MBAS or CTAS, it is important to obtain a preinjection baseline analysis. MBAS mostly picks up anionic surfactants and CTAS mostly nonionic surfactants. Some surfactants cannot be detected by either method. | Reassess location, depth, volume, and delivery pressure of amendment injections to establish adequate concentrations of surfactants to mobilize NAPL. |

There are many remediation sites where multiple remediation technologies have been or are being pilot tested, deployed sequentially, or deployed simultaneously (by design or otherwise) (Appendix E.10, LNAPL Remediation Combining Mobile Dual Phase Extraction with Concurrent Injection of a Carbon-based Amendment). Because the application of most remediation technology classes involves the temporary or permanent alteration of subsurface conditions, it is appropriate to evaluate the potential impacts the other technologies may have on the effectiveness of the proposed technology. For instance, significant organic carbon increase may exert a significant oxidant load above and beyond NOD. The types of analytical tests used for a site-specific monitoring program will vary depending on the chemicals known or suspected of being used previously (either the contaminant or amendment), the amendments expected to be used in the remedial action, and the local geology and geochemistry.

Molecular diagnostics such as quantifying the abundance of degradative bacteria (Section 4.4.4.1 and Section 4.4.4.2) are often included in the analytical suite to serve as additional lines of evidence to confirm contaminant degradation. Given their expense, however, these analyses are generally included less frequently (or applied at only a subset of wells within the network) than the monitoring of primary COCs and geochemistry. Additional information beyond what is provided below may be found in see “Environmental Molecular Diagnostics—Facts Sheets” (ITRC 2011b).

4.4.4.1 Abundance of Bacterial Groups

4.4.4.2 Shifts in Isotopic Signature

4.4.5 Monitoring Data Assessment

Data evaluation and interpretation are key components to assess whether remedial objectives are being achieved and at a sufficient rate (i.e. is performance of a remedial approach indicative of a successful outcome?). A variety of tools and methods can effectively evaluate data to establish whether progress toward objectives is being made, generally including updating the CSM, statistical analysis, and modeling, which can include predictive and validation modeling.

In reviewing or evaluating the adequacy of the performance monitoring data, the following questions should be asked:

- Are the correct media and zone of contamination being monitored?

- Are the monitoring locations in sufficient quantity and located at distances to allow reliable data to be collected regarding injection distribution and concentration reduction?

- Is the correct delivery mechanism being used to implement the technology?

- Are the COCs and all potential byproducts being monitored?

- What other parameters represent lines of evidence to support the remedial goals for the site in question?

- Is the current level of data collection sufficient to enable the performance metrics to be analyzed?

Performance parameter selection depends on the type of in situ technologies applied (for example, ISCO, bioremediation, etc.). The parameters to be monitored should coincide with the baseline sampling and with evaluating the end points. Performance data may include geochemical, hydrogeologic, and microbial data along with the evaluation of chemical, physical, or biological processes in the subsurface.

Tracking changes in geochemistry is also useful in evaluating the long-term effectiveness of a prescribed injection system. It is common to simultaneously evaluate geochemical parameters while performing groundwater monitoring events. However, geochemical parameters may be evaluated on a different frequency. Evaluating geochemical changes versus time can aid in evaluating the subsurface activity and distribution of the injected material. For example, a significant increase in methane concentration within the hot spot of a petroleum plume or after an anaerobic substrate injection would indicate an increase in microbiological activity in the affected area. Additionally, geochemical isopleths aid in visualizing the extent of an injection’s dispersion. Conversely, no change in geochemistry may indicate the injected material has not reached or sufficiently affected its intended target area. Other factors could contribute to system performance that does not meet design expectations. Please refer to Section 1.3 to identify a path forward once performance is deemed inadequate.

Performance monitoring is an iterative process and will need to be completed throughout treatment to provide information for optimization. These questions will provide a basis for this monitoring, and if inadequate performance is identified, the information in Section 2 can be used to evaluate next steps.

To assess overarching functional objectives such as exposure, extent, fate, and transport of COCs in a source zone or plume, as well as progress on remedial actions, SMART attributes (specific, measurable, attainable, relevant, and time bound see ITRC 2011c for a description of SMART objectives and the assignment of attributes) need to be assigned to the remedial objectives. This process will define a specific measurable quantity or metric for each medium to be monitored. When setting SMART attributes for the remedial action, each attribute should be considered and modified to be site-specific. The following provides an overview of key performance metrics to consider in setting up the monitoring program.

4.4.5.1 Concentration

4.4.5.2 Mass

4.4.5.3 Mass Flux/Discharge

4.5 Implementation Optimization

Optimization improves the protectiveness and cost-effectiveness of remedial actions. This is consistent with the general definition given in the ITRC Remediation Process Optimization guidance document (ITRC 2004), which emphasized efforts to maximize protectiveness and minimize cost. As used in this document, optimization is defined in a more rigorous way, emphasizing the process to make remedial efforts “…as fully perfect, functional or effective as possible” (Section 4.4.2.1). Optimization can be quantitative (formal) or qualitative.

Agencies at the local, state, and federal levels and private sector have worked over the years to use optimization practices and come to a consensus on optimization lessons learned and optimization reviews and how they apply to ongoing environmental projects throughout the regulatory process for the benefit of all. Where applicable, optimization stakeholder meetings and other aspects of optimization activities may be considered (USEPA 2013).

4.5.1 Formal Optimization Techniques

4.5.2 Optimization and Verification of Treatment Effectiveness

4.5.3 Changing Conditions

4.5.4 Subsequent Amendment Applications

4.6 Transition and Contingency Planning

Two types of conditions have been identified to require transition and contingency planning: anticipated subsequent application events that are commonly included with in situ injection programs (for example, ISCO), and unexpected conditions that may occur related to injection events. Both conditions are addressed with the suggested contingencies. The practitioner must consider the risk of these conditions for the site during the planning stage of the project and develop contingencies for those risks so a contingency plan can be implemented quickly.

When the risk justifies it, a mitigation or contingency strategy is developed. This risk management approach is outlined in Project Risk Management for Site Remediation (ITRC 2011d). The approach involves the preparation of a risk register that summarizes the various risks and their likelihood and impact. If the risk is small (highly unlikely or very minor impact), the risk can just be accepted. If the risk is substantial (likely occurrence and significant impact on cost and schedule), then there should be a plan to address this if the condition occurs.

4.6.1 Intentional Transition Planning

4.6.2 Contingent Remedy Transition Planning

Click here to download the entire document.